Caviar Production: How is Caviar made?

Caviar production has completely transformed in the last twenty years. Once almost entirely dependent on wild sturgeon from the Caspian Sea, today more than 95 % of all caviar sold in Europe comes from sustainable farms. These farms raise ancient fish in clean, controlled water, harvest the eggs humanely, and deliver pearls that are fresher, more consistent, and often tastier than the wild caviar of the past. This guide explains every part of modern caviar production from choosing the right baby fish to the moment the tin reaches your table.

The Fascinating History of Caviar

The story of caviar production begins over 2,500 years ago on the shores of the Caspian Sea. Ancient Persians were the first to salt sturgeon eggs. Caviar was knwon as the cake of strength; because they believed the roe restored energy after illness or hard work. By the Middle Ages, Russian fishermen supplied salted eggs to tsars and nobles. In the 1800s caviar became so common in America that New York bars gave it away free with beer to make customers thirsty.

Everything changed in the 20th century. Overfishing, poaching, dams, and pollution crashed wild sturgeon numbers. Beluga, osetra, and sevruga became critically endangered. In 1998 the United Nations listed nearly all sturgeon species under CITES protection, and by 2006 most wild caviar trade was banned. Farms saved the day. Today the full history of caviar reads like a dramatic rescue: from everyday food to near extinction, and now to a thriving, planet-friendly luxury.

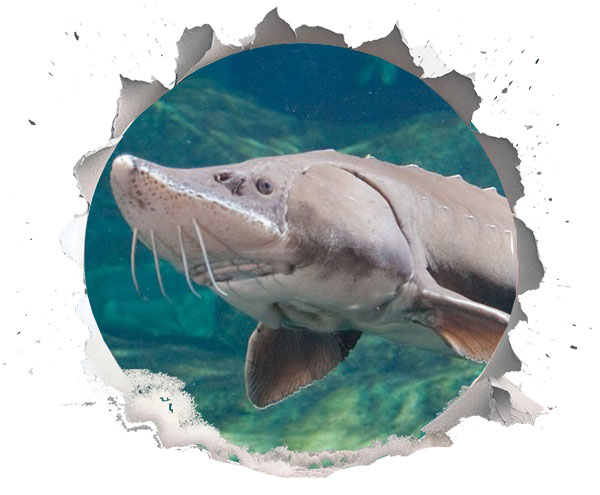

The Only Fish That Gives True Caviar

True caviar comes only from sturgeon, a family of 27 ancient species that have barely changed in 250 million years. They have bony plates instead of scales, long snouts, and can live over 100 years. The most prized for caviar production are:

- Beluga (Huso huso) – the largest eggs, soft and buttery

- Osetra (Acipenser gueldenstaedtii) – golden-brown, nutty, firm pearls

- Sevruga (Acipenser stellatus) – small, dark, intense burst

- Siberian sturgeon (Acipenser baerii) – reliable and smooth, the workhorse of modern farms

- White sturgeon (Acipenser transmontanus) – mild and creamy, popular in the USA

Females take 7–20 years to mature and produce eggs, which is why real caviar will always be special and costly.

Why Sustainable Caviar Is the Only Future

Modern caviar production is built on sustainability. Farms use recirculating aquaculture systems (RAS) that clean and reuse 98 % of the water. Plants, bacteria, and UV filters remove waste naturally. Many farms now practise “no-kill” harvesting; the fish is lightly sedated, the eggs are gently massaged or stripped through a tiny incision, and the sturgeon swims away to produce more roe in future years.

Leading sustainable caviar producers are found in Italy, France, Germany, Spain, the United States, China, and Iran. All reputable brands carry independent certifications (ASC, GlobalG.A.P., EU organic, or Friend of the Sea) so customers can trace every gram from pond to plate. Choosing sustainable caviar protects wild sturgeon populations, keeps rivers clean, and guarantees the highest quality eggs.

Inside Culture Caviar’s Farm

Culture Caviar farm’s caviar production is sustainable. Rooted near the Caspian Sea in Iran, and with almost 40 years of know-how, We mix ancient Persian ways with modern tools for top-grade roe. We span clean lands fed by fresh springs. No wild catch here; all sturgeon bred on site in vast ponds and tanks that echo river homes.

It starts with breeding. Healthy pairs, free of disease, lay eggs in controlled nests. Hatchlings, tiny as pins, fill nurseries with bubbling water at 18°C. Oxygen pumps keep them lively; pH stays steady at 7.5. As they grow, juveniles shift to grow-out ponds; shallow basins with gravel floors for rooting. Water flows slow, filtered through sand and UV lights to zap bacteria. Daily checks cover temperature (16-20°C), oxygen (over 6mg/L), and clarity. If levels dip, aerators kick in.

Feed is simple and pure. Pellets blend Caspian shrimp meal, algae, and vitamins; no antibiotics or fillers. This builds eggs plump with fats, mimicking wild diets. Sturgeon mature in 7-10 years, faster than beluga’s 20 but with same creaminess. Each fish gets a tag for tracking: growth charts, vet notes, even mood via swim patterns.

Harvest day is art. Experts scan with ultrasound for ripe ovaries—eggs at stage IV, glossy and loose. Fish move to a quiet room, sedated softly. An incision frees the skein; hands in gloves tease eggs free. Rinse in chilled brine (3% salt) removes bits. Sort by hand: size (2-3mm), colour (grey to gold), firmness. Labs test for metals.

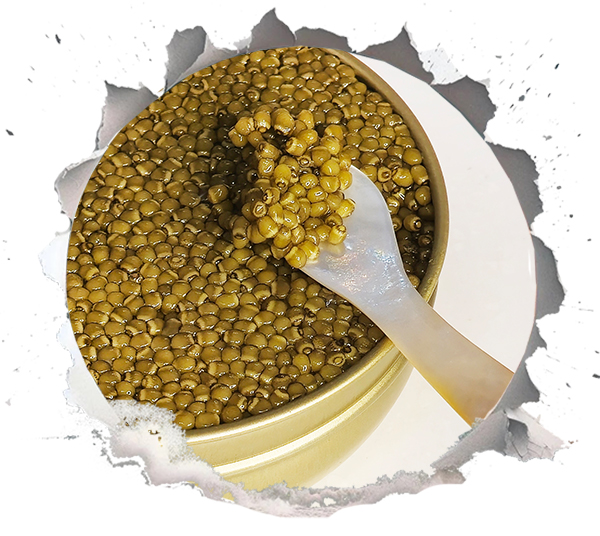

Curing follows fast. Malossol style adds 3-5% salt for light taste, drained after minutes. Pack in tins from 30g to 1kg, sealed in sterile rooms. From pond to chill, hours pass, keeping oils fresh. Culture Caviar shines in green steps. Closed loops recycle 98% water; waste feeds local farms. They meet EU and US rules, exporting to Europe with full traces.

Their range delights: Beluga Imperial, large and buttery; Almas, rare white pearls; Ossetra, nutty gold. This process honours roots while guarding tomorrow. At Culture Caviar, every tin tells of care; from Caspian whispers to your plate.

Step-by-Step: How Caviar Production Works Today

- Breeding and hatching Healthy parent fish spawn in spring-like conditions. Eggs hatch in 7–10 days.

- Nursery stage (first 12–18 months) Tiny fry live in warm, shallow tanks with constant gentle water flow.

- Grow-out phase (6–15 years) Juveniles move to large ponds or indoor RAS tanks. Water quality is checked several times a day.

- Maturity check Ultrasound and small biopsies show when eggs are glossy, loose, and ready.

- Harvesting Light sedation → incision→ roe removed.

- Cleaning and sieving Eggs are rinsed in ice-cold 3 % brine and passed through fine mesh sieves to separate each pearl.

- Malossol salting Pure salt is mixed in by hand for 5–15 minutes, then drained.

- Grading Sorted by size, colour, and firmness.

- Packing and chilling Sealed in lacquered tins or glass jars, cooled to –2 °C, and shipped in temperature-controlled boxes.

The whole caviar production chain is traceable, certified, and designed to deliver the freshest possible product to Europe’s best restaurants and shops.

The Main Types of Caviar Available in Europe

- Beluga – largest pearls (3–4 mm), pale to dark grey, melts like butter, £3,500–£8,000 per kg

- Ossetra (or Osetra) – medium size, golden to dark brown, rich nutty taste, £1,200–£3,000 per kg

- Sevruga – smallest pearls, grey-black, strong sea burst, £800–£1,800 per kg

- Siberian / Baerii – smooth, medium eggs, excellent everyday caviar, £600–£1,200 per kg

- Albino or Golden caviar – extremely rare white or pale gold pearls, sometimes £10,000+ per kg

Farmed caviar is more consistent in size and flavour than wild ever was.

Nutrition in Every Spoonful

A modest 30 g serving (about two tablespoons) contains:

- 75 calories

- 7 g high-quality protein

- 1,800–2,500 mg omega-3 (EPA + DHA) – far more than most salmon portions

- 236 % of daily vitamin B12

- 65 % daily selenium (powerful antioxidant)

- Good amounts of iron, zinc, vitamin D, and vitamin E

The long-chain omega-3 fats support heart health, reduce inflammation, improve brain function, and keep skin smooth and firm. Many luxury skincare brands now use caviar extract for the same reason. Scientific studies confirm these caviar benefits make it one of the most nutrient-dense foods you can eat.

Why Caviar Still Costs a Lot (and How to Avoid Fakes)

Even sustainable farmed caviar is expensive because:

- Fish take 7–20 years to mature

- Only female sturgeon produce roe

- Every step is done by hand by skilled workers

- Strict EU and international food-safety rules

Always buy from sellers who provide certificates of origin, lab reports, and CITES documentation if required. If a 50 g tin costs less than £80–100, it is almost certainly not real sturgeon caviar.

The Bright Future of Caviar Production

New farms are opening every year in Germany, Poland, Spain, and even indoor city farms in the Netherlands. Some producers release millions of baby sturgeon into rivers to rebuild wild populations. Advances in water recycling, LED lighting, and gentle harvesting mean caviar production is becoming cleaner and more efficient every season.

Caviar production today is one of food’s greatest success stories: a delicacy that nearly vanished, now thriving because people chose sustainability over short-term profit. When you open a tin of perfectly salted pearls, you are tasting centuries of tradition; and supporting a future where both sturgeon and luxury can flourish together.