Modern Luxury Food Processing in Berlin, Germany

Berlin has always resisted easy definitions. It is a city shaped by rupture and reinvention, a place where abandoned factories became art spaces, where political gravity met creative rebellion. Yet beneath its cultural noise and industrial past, something quieter and far more refined has been taking shape. Berlin is emerging as a serious force in luxury food processing in Germany, redefining what high-end production looks like in Europe. Not loud. Not obvious. But precise, technical, and deeply intentional. For those watching closely, Berlin is no longer just a stage for ideas. It is becoming a laboratory, one where food technology, logistics, sustainability, and craftsmanship converge. And in this intersection, luxury finds a new, modern expression.

From Grit to Precision: Berlin’s Industrial Reinvention

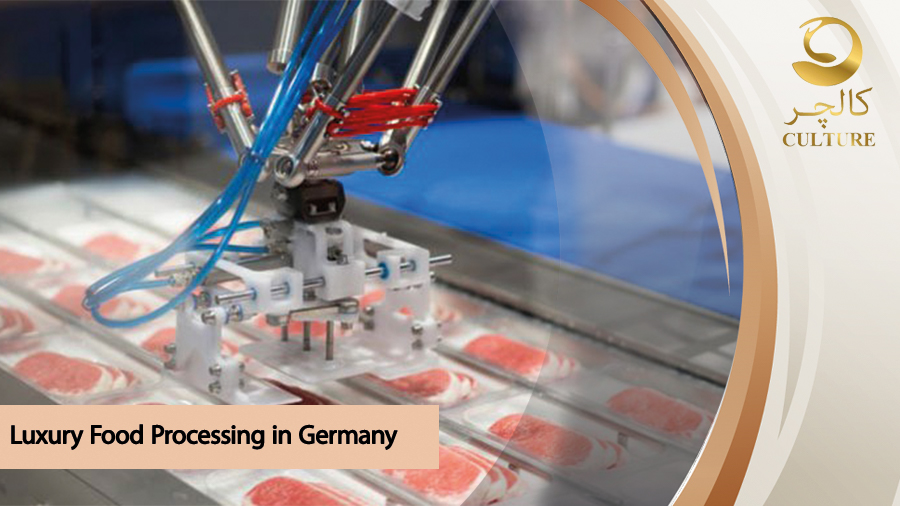

At first glance, Berlin does not resemble the polished image traditionally associated with luxury food processing. Its aesthetic heritage is industrial, functional, and often deliberately raw. Yet this history has become its greatest asset. The same warehouses that once powered heavy industry now house sterile, climate-controlled, ISO-certified food processing facilities. High ceilings allow for modular production lines. Thick concrete walls stabilise temperature. Former logistics zones have become hubs for advanced cold-chain infrastructure. Berlin’s transformation mirrors a wider European shift: luxury today is no longer about gold trims and spectacle. It is about control, cleanliness, traceability, and trust. And Berlin excels at that.

Berlin Food Tech: Where Engineering Meets Taste

At the heart of Berlin’s rise in luxury food processing is a distinctive fusion where meticulous German engineering is applied not to machinery, but to taste itself. This is not about replacing the artisan’s touch with cold automation; rather, it’s about creating a technological environment so precise and reliable that craftsmanship can flourish without inconsistency. The pragmatic integration of automated quality-control systems and data-driven batch tracking provides a silent, unwavering foundation. This allows producers to focus on the nuanced art of flavour development, secure in the knowledge that every variable, from ambient humidity to water purity, is held within a scientifically defined golden standard. The result is a process where technology acts as the guardian of quality, ensuring that each batch of a delicate product meets an exacting standard that the human senses alone could never guarantee.

This engineering-first approach directly serves the core demand of the international luxury market: impeccable and reliable consistency. For a high-value product, whether it is cured meat, artisan chocolate, or caviar, the slightest deviation in process can alter texture, flavour, or shelf life. Berlin’s facilities address this by building what is essentially a laboratory-grade ecosystem for production. Precision climate regulation and advanced water filtration are not just features; they are the essential tools that allow for the microscopic control of maturation and preservation. In this context, modern science doesn’t overshadow tradition; it rigorously protects it. The artisanal quality is not compromised by scale or distribution; instead, it is encapsulated and preserved by technology, enabling Berlin’s producers to deliver their taste profiles faithfully to tables across the globe.

Consequently, Berlin enters the conversation on luxury food processing in Germany not as an imitator of established pastoral regions, but as a distinctly modern alternative. Its offering is flexibility without compromise; the ability to handle small, exclusive batches with the same rigorous control as larger runs, all within a dynamic, urban hub designed for global logistics. This agility, rooted in a tech-enabled infrastructure, means Berlin can cater to innovative chefs and evolving brands that require both supreme quality and adaptive production solutions. It is this synthesis of cutting-edge food tech with a profound respect for the sensory outcome that allows Berlin to stand alongside traditional centres, offering a new model where the confidence in the product is born from the certainty of the process.

Water, Environment, and the Science of Purity

Luxury food processing begins long before a product reaches the production line. It starts with environmental control, particularly water. Berlin benefits from access to tightly regulated water systems, advanced filtration infrastructure, and scientific oversight that meets some of the strictest EU standards. In high-end food processing, even minimal variations in mineral composition can affect flavour, texture, and shelf stability. The industry’s growing focus on water quality influence reflects this reality. Berlin processors invest heavily in monitoring systems that ensure absolute consistency, allowing premium products to maintain their sensory integrity across batches. This attention to invisible details is what separates industrial food production from true luxury processing.

Luxury Food Processing Germany and the Berlin Advantage

Germany’s reputation for precision manufacturing is well established. What Berlin adds is adaptability. Unlike traditional food regions tied to legacy models, Berlin’s processing landscape is younger, more agile, and designed for modern supply chains. Facilities are built with international distribution in mind, not just local markets. This makes Berlin especially attractive for:

- Export-focused luxury brands

- Products requiring rapid EU-wide delivery

- Controlled, small-batch premium processing

When discussing luxury food processing in Germany, Berlin represents the future-facing edge of the sector; technically advanced, logistically smart, and globally connected.

An EU Logistics Hub Built for Speed and Integrity

Berlin’s central position in Europe and its advanced, integrated logistics transform speed into a guarantor of quality for luxury food. The 48-hour delivery reach to most EU markets, supported by seamless air, road, and rail links managed by specialised cold-chain providers, is fundamentally about preservation. This turns the city into far more than a production site; it becomes a distribution nerve centre where shorter transit times minimise handling risk, ensuring products arrive in optimal condition and elevating Berlin’s role from processor to Europe’s strategic hub for premium food dissemination.

Processing Excellence Behind the Scenes of Modern Caviar

Nowhere is Berlin’s quiet competence more visible than in high-value niche sectors like premium caviar processing. Berlin facilities specialising in refined aquatic products operate with a level of discretion and technical mastery that aligns perfectly with luxury expectations. Here, innovation supports tradition, rather than replacing it. Research into sturgeon farming techniques informs processing decisions, allowing producers to handle roe with extraordinary sensitivity. Temperature, salinity, and maturation environments are meticulously calibrated to preserve structure and flavour. Berlin does not position itself as a romantic origin story; it positions itself as the place where excellence is protected. Our farms at Culture Caviar draw direct inspiration from Germany’s pioneering models, adapting their advanced technological approach to cultivate caviar that achieves both exceptional quality and sustainability.

Sustainability Without Theatre

In luxury food today, sustainability is not a marketing accessory. It is a requirement. Berlin’s processing sector reflects Germany’s broader commitment to environmental accountability. Energy-efficient facilities, water recycling systems, and waste-reduction protocols are standard rather than exceptional. This is particularly relevant in premium segments where ethical sourcing and long-term viability matter. The concept of sustainable caviar has moved from aspiration to operational reality within Berlin’s ecosystem. Transparency, compliance, and environmental stewardship are embedded into processing workflows, offering reassurance to partners and consumers alike.

Caviar, Reimagined in a Modern Capital

The phrase Caviar Berlin may surprise some, but it captures something essential about the city’s evolving identity. Berlin does not compete with traditional luxury capitals by imitation. Instead, it reframes luxury through clarity, discipline, and modernity. Caviar processed here is not about spectacle; it is about confidence in process, environment, and delivery. The city’s understated approach appeals to a new generation of luxury buyers and partners: informed, globally minded, and deeply attentive to quality over image.

Factories as Destinations: Experiential Luxury Processing

An emerging trend in Berlin’s luxury food sector is openness, controlled, curated openness. Select processing centres now welcome partners, buyers, and collaborators for guided, invitation-only visits. These are not tours designed for show, but immersive experiences that demonstrate precision, cleanliness, and technical expertise. Glass-walled production areas, laboratory-grade hygiene standards, and transparent workflows turn processing into a statement of credibility. The factory becomes not just a workplace, but a destination, a place where trust is built face to face. For B2B partners, this level of access transforms relationships from transactional to collaborative.

Why Berlin Appeals to Global Luxury Partners

Berlin’s appeal lies in its balance:

- German regulatory reliability

- European logistical reach

- A culture comfortable with innovation

- An absence of unnecessary extravagance

For international partners seeking long-term processing solutions, Berlin offers stability without stagnation. Its luxury food sector is designed to evolve alongside changing market demands, sustainability standards, and consumer expectations. In a world where luxury increasingly values responsibility, Berlin feels remarkably aligned with the future.

The Future of Luxury Food Processing Germany Starts Here

Berlin is not loudly claiming its place in luxury food. It doesn’t need to. Its strength lies in what happens behind closed doors, in controlled environments, calibrated systems, and decisions guided by data rather than tradition alone. This is a city that understands that modern luxury is built quietly, consistently, and with intent. As luxury food processing in Germany continues to evolve, Berlin stands as an unexpected yet inevitable leader. A city where industrial heritage meets refined purpose, and where the future of European luxury processing is already being shaped. For those willing to look beyond the obvious, Berlin is no longer just a cultural capital. It is a processing capital, and one worth paying attention to.

FAQ

Berlin excels in processing high-value, perishable goods where technical control is critical. This includes premium aquatic products like caviar, delicatessen meats, artisan chocolates, and other items requiring meticulous maturation, precise climate control, and rigorous batch integrity for international export.

Berlin acts as a single, compliant EU entry and distribution nexus. A brand can process and warehouse centrally in Berlin, leveraging its integrated cold-chain and transport networks to reach the entire EU market efficiently, simplifying customs and reducing overall supply chain complexity.

Sustainability is operational and intrinsic, not a marketing veneer. It is embedded through engineered efficiencies—like water recycling in production, energy recovery systems, and waste reduction protocols—that align with the luxury sector’s growing demand for verifiable environmental accountability.

Yes, its agility is a key advantage. Unlike larger, traditional processors geared for high volume, Berlin’s tech-enabled facilities are designed for flexibility, making them ideal for limited editions, pilot batches, and collaborations where precision and adaptability are equally important.